- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

Discover our high-performance bottle filling production line for water, juice, and soft drinks. Full turnkey design with capacities from 6000BPH to 72000BPH.

A bottle filling production line is more than just a set of machines — it’s the backbone of modern beverage manufacturing. From forming bottles to packaging finished products, a well-designed production line ensures efficiency, consistency, and hygiene. Whether you're producing still water, flavored drinks, or carbonated beverages, our systems are tailored to your production needs.

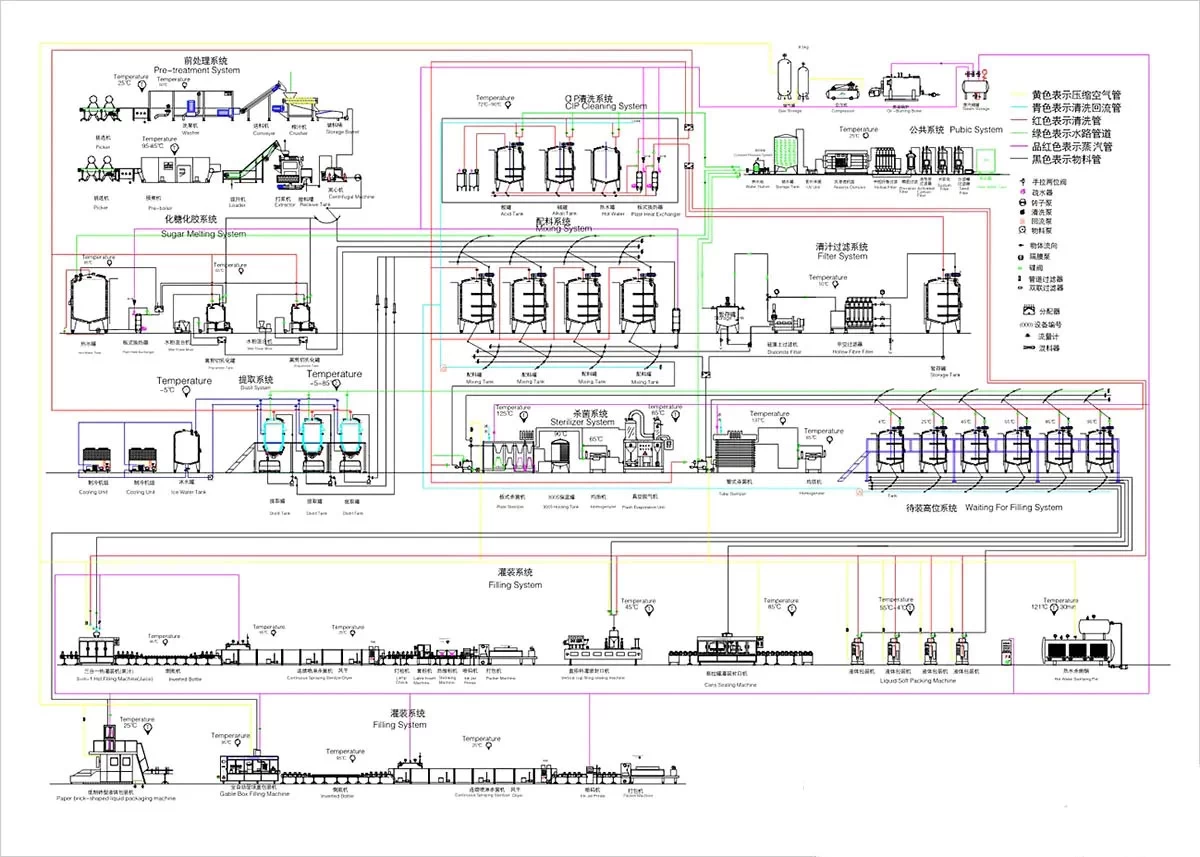

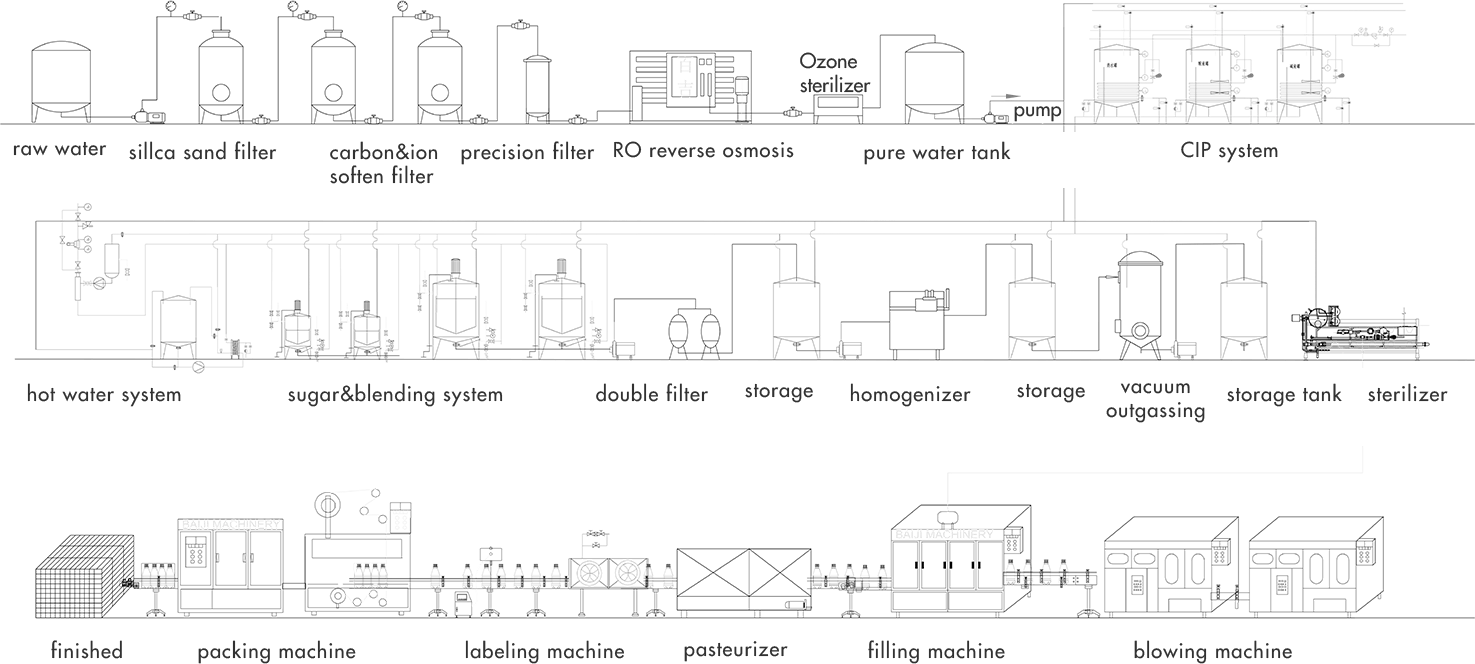

Our complete bottle filling lines are modular and flexible, typically consisting of the following key sections:

- Blow Molding: Produces PET bottles from preforms.

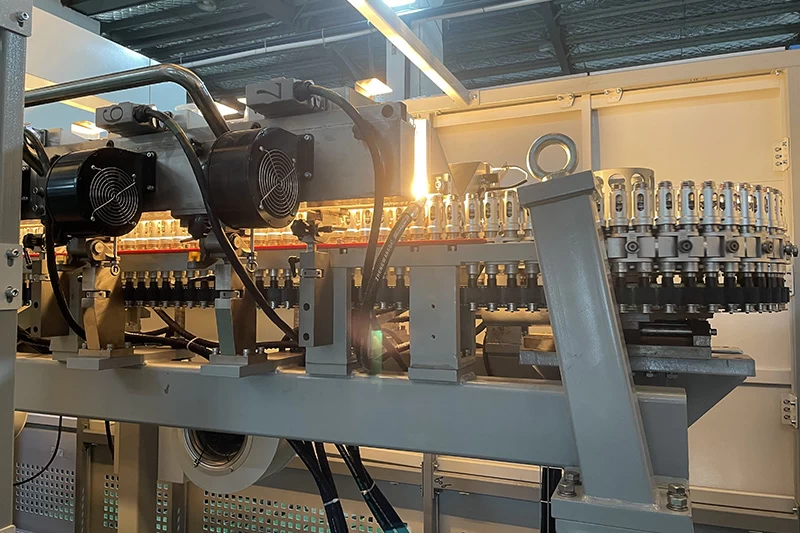

- Rinsing Unit: Ensures bottle cleanliness before filling.

- Filling Station: Gravity or isobaric filling for various liquids.

- Capping Machine: Securely seals bottles of all sizes.

- Labeling: Supports OPP, sleeve, or adhesive labeling.

- Shrink Packaging: Bundles products for retail.

- Palletizing: Automates stacking for easy shipping.

We offer standard and customized configurations based on production needs:

- 6000–72000 Bottles Per Hour (BPH)

- Bottle volumes: 330ml, 500ml, 1L, 1.5L, 5L

- Applications: Bottled water, fruit juice, soda, energy drinks

Whether you're a startup or a high-output factory, we tailor the right setup for your plant size, energy usage, and bottle design.

- Compact line layout saves factory space

- Fully automated system reduces labor costs

- Hygienic design meets international food safety standards

- Low maintenance and high uptime

- Over 50+ turnkey installations across Africa, Middle East, and Southeast Asia

• Kenya: 24000BPH Water Line with Sleeve Labeler

• Vietnam: 12000BPH Mixed Juice Line (500ml + 1.5L combo)

• Saudi Arabia: 36000BPH Sparkling Water Plant with robotic palletizing

Q: How long does installation and commissioning take?

A: Typically between 30 to 60 days depending on line complexity.

Q: Can the line handle both 500ml and 1.5L bottles?

A: Yes, changeovers are simple with modular design.

Q: Is the line suitable for carbonated drinks?

A: Absolutely. We use isobaric filling systems for soda and CSD.

Fruit juice beverage production equipment:

cleaning (washing machine) - fruit inspection (fruit inspection machine) - crushing (crusher) - pulping (pulping machine) - juicing (juicer) - filtration (filter) -Concentration (concentrators) - Blending (blending tanks) - Sterilisation (sterilisers) - Aseptic storage (aseptic tanks) - Aseptic filling - Secondary sterilisers -labelling machines - coding machines - automatic packaging machines - palletising machines

According to the positioning of juice products and different production processes, the equipment used is also slightly different, Comenster team to provide you with professional juice production line solutions, according to your market positioning, product characteristics, we provide from the juice product development and design, juice production line design, planning and design of the whole set, bottle design, packaging options, marketing and other comprehensive all-round services.

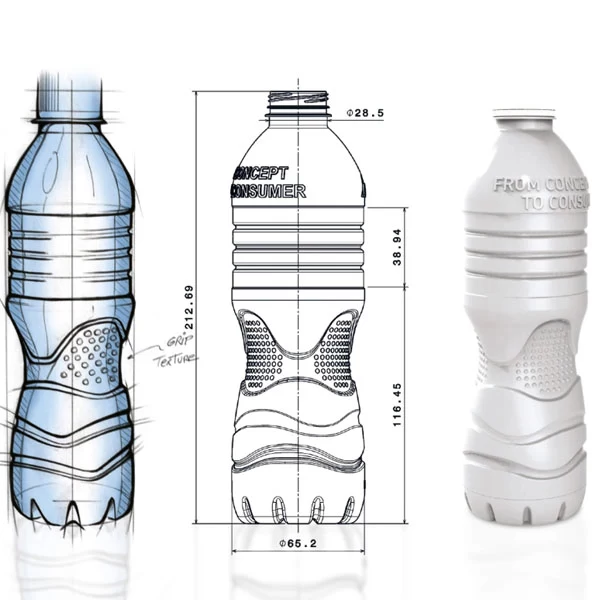

Bottle Type design:

Comenster professional technical team, according to your needs for free bottle design, for you to recommend the right bottle structure, to increase the competitiveness of your products in the market, and at the same time according to the market situation of your country for you to recommend the right bottle type.

According to the different needs of customers and bottle drawings, customize the filling and packaging equipment scheme.

As shown below:

We can supply bottle preform, caps, label rolls with very reasonable price.

Choose the right production line according to the fruit category:

Orange juice production line

Mango juice production line

Pineapple juice production line

Apple juice production line

Blueberry juice production line

Blackcurrant Pressed Juice production line

According to the juice production process to choose the right production line:

Aseptic Cold Filling Juice Production Line

Hot Filling Juice Production Line

According to the juice packaging form to choose the right production line:

PET plastic bottle juice production line

Glass bottle juice production line

Easy-pull juice production line

Tetra Pak Juice Production Line

Bag Juice Production Line

Comenster Machinery is one of the leading juice production line manufacturers and suppliers in China, serving and meeting the growing demand for high quality juice products. Our production lines are centrally controlled, technologically advanced, and require high precision to ensure that the juice is processed efficiently, effectively and reliably, and our juice production line has a full set of equipment for juicing, filtering, mixing, sterilising and packaging, which can meet different production requirements.

We cater to a wide range of applications including extraction and processing of fruits, vegetables and other ingredients, high concentration fruit juice concentrates, etc. to produce quality fruit juices that meet international standards. As a trusted factory, we ensure the use of quality materials and adhere to stringent quality control standards to provide the best juice production line solutions. Our experienced technicians and engineers provide quality customer support, installation and commissioning services, and troubleshooting services to ensure prompt and reliable operation of the equipment. If you are looking for a reliable juice line supplier in China, Comenster Machinery is your first choice. For more information about our products and services, please contact us.

Having Customer Service is very important, but that's just the way it is.